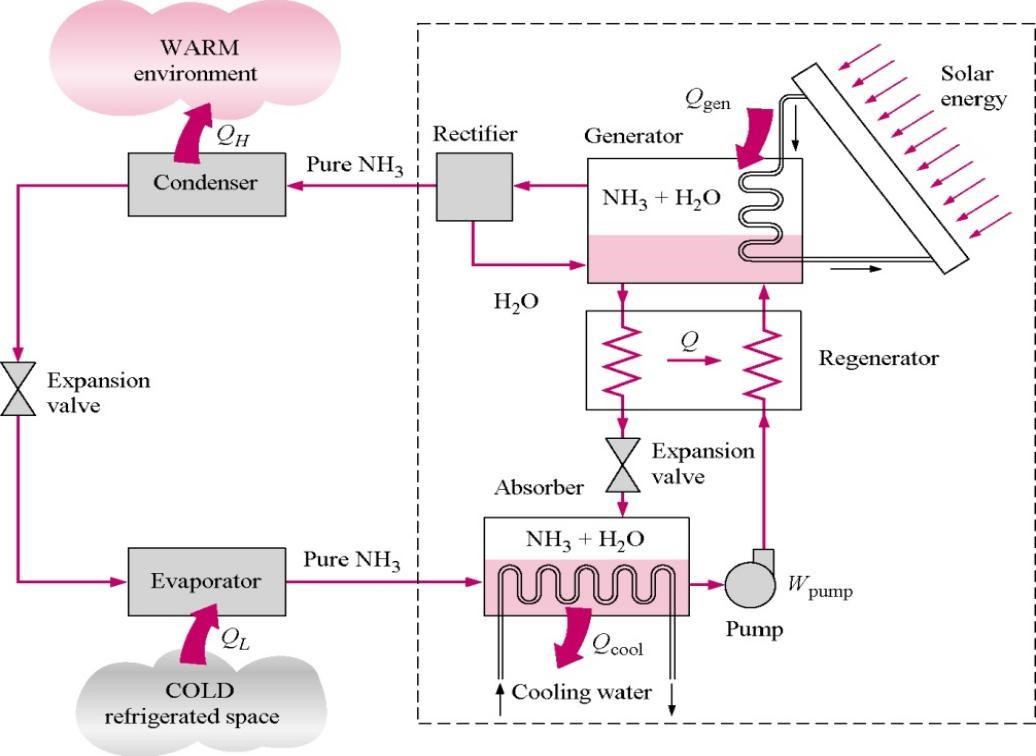

The VAR system is just like the VCR system except that the compressor has been replaced by a complex absorption mechanism consisting of an absorber, a pump, a generator, a regenerator, a valve, and a rectifier. The vaporized refrigerant leaves the evaporator and enters the absorber at low-pressure, where it dissolves and reacts with the absorbent to form a solution. Heat is released during this process, making it an exothermic reaction. The amount of refrigerant that can be dissolved in the absorbent is inversely proportional to the temperature.

It is therefore necessary to cool the absorber to maintain its temperature as low as possible, hence maximizing the amount of refrigerant dissolved in the absorbent.

The liquid solution which is rich in the refrigerant, is pumped to the generator.

The heat energy from the exhaust gas is then transferred to the solution at the generator to vaporize some of the solution. The boiling point of the refrigerant is lower than that of the absorbent thus the vapor leaving the generator is rich in the refrigerant [5], passing through the rectifier, which separates the absorbent from the refrigerant and returns it to the generator. The high pressure pure refrigerant vapor then continues through the cycle. Meanwhile, due to the generation of refrigerant vapor, weak absorbent solution is sent back to the absorber while passing through an expansion valve [4].

Traditionally, vapor compression systems are more popular when it comes to the choice of refrigeration systems onboard the vessel as compared to the vapor absorption refrigeration systems. Vapor compression refrigeration systems are powered by electrical energy generated by the burning of increasingly costly fuel. The complexities of environmental sustainability and the energy economy have contributed to a growing interest in non-conventional refrigeration systems such as absorption refrigeration.

The VAR system has always attracted an increasing deal of interest thanks to such advantages as utilization of inexpensive sources of energy (low-grade and renewable heat sources) and environment-friendly working fluid pairs (refrigerants that have almost no ODP and GWP). As refrigerants with ODP and GWP are being phased out, the use of the VAR system is being encouraged. However, this technology suffers from few drawbacks which include too large size of the cooling unit and the low COP of the refrigeration system, preventing the absorption systems from being commercially successful.

To better understand the merits of the VAR system, it is compared to the conventional VCR system. There are numerous advantages that the absorption system has over the compression system which include the moving parts of the system, the type of refrigerant being used, the quality of the refrigerant, how load variations affect the performance, the amount of power required to run the unit and the ease of maintenance of the unit among others [6].

Moving Parts:

The only moving component of the absorption refrigerator is the pump which delivers the refrigerant-absorbent mixture to the other components. When compared to the compressor of the vapor compression system, it is smaller in size and does not cause much noise and vibration. The work done by the pump is so small that it is often neglected in thermal analysis of the system. The pump gives the vapor absorption system an added advantage of being much less noisy compared to the vapor compression system.

Type of refrigerant used:

One of the biggest benefits of the vapor absorption system is that it uses refrigerants that have no ODP and GWP. The refrigerant-absorbent pairs also have great affinity to each other causing no complex chemical reactions which may have an adverse effect on the environment.

Quality of refrigerant:

The temperature of the vaporized refrigerant leaving the generator is slightly superheated as it enters the condenser. But, for the vapor compression system the degree of superheat is dictated by the suction state of the vapor, resulting in much higher superheated temperatures within the system at the end of compression. This indicates that the vapor absorption system requires a much smaller condenser compared to the vapor compression system.

Load variation does not affect the performance of the system:

The same value of COP can be maintained even after changes in the generator and evaporator temperatures by appropriate control of generator temperature. If evaporator temperature drops, the COP of the unit can be maintained by increasing the generator temperature. Therefore, at partial loads performance of the system is not affected. This feature is one of the most desired in the V.A.R system.

The amount of power required:

The pump in vapor absorption refrigeration system requires a very small amount of power and it remains almost the same in size for even higher capacities of refrigeration or may increase slightly. But in the case of vapor compression, the compressor requires a large amount of power for its operation and it also increases in size depending on the refrigeration capacity.

Maintenance:

Since the pump is the only moving part of the vapor absorption system, maintenance is comparatively easier than the vapor compression system. Other components are cleaned for effective heat transfer.

The VAR refrigeration system, although having many strengths, also has some weaknesses which offset its convenience. These have been a major cause of concern for most people for many years.

The disadvantages of the VAR systems include but are not limited to its high initial cost, low working pressures, the low COP of the system, the large size of the cooling unit, complex design, larger space requirement for installation of the unit, lack of manpower for servicing [7].

Higher Initial Cost:

Although the running cost of the absorption unit is very low, its initial cost is high. This can be attributed to a number of factors namely the complex absorption system replacing the compressor of the vapor compression system which contributes to the size of the plant and the size of the cooling unit.

Occupies more space:

Since the compressor of the Compression refrigeration plant is being replaced by a complex absorption system comprising of the absorber, generator, rectifier, etc. for the absorption refrigeration system, more space is required to accommodate this system.

They are more complex:

Due to the number of components and complexity in design of the VAR system, they are more complex. This makes it harder to service and install.

The large size of the cooling unit:

They are much less efficient thus require much larger cooling towers to reject the waste heat for the same cooling capacity.

Servicing:

They are more difficult to service since they are less common. As a result, there are less specialized personnel to service it. This drives ship owners from going for the VAR system [30].

COP of the system is much lower than the VCR system:

The COP of the unit is relatively low, with simple compression refrigerators achieving a COP of about 3.5, simple absorption refrigerators achieve COPs ranging from 0.5-1.6.

Learn more about the Coefficient of Performance (COP) of the VAR system of refrigeration.